I was pleasantly surprised with the sturdiness and height of the molds. Just plan on a bit of hard work. You really need 3-4 of these molds to make the work go a lot easier & faster

A Concrete Paver Mould Which Is Super Easy To Use, No Special Skills Required, Even An Inexperienced Person Can Build A Beautiful Pathway

These pavement moulds are made of high quality plastic & will last a lifetime. Fully reusable & easy to clean with water after use

Reusable Concrete Mould | Stepping Stone Paver Walk Way Mould

$39 – $55

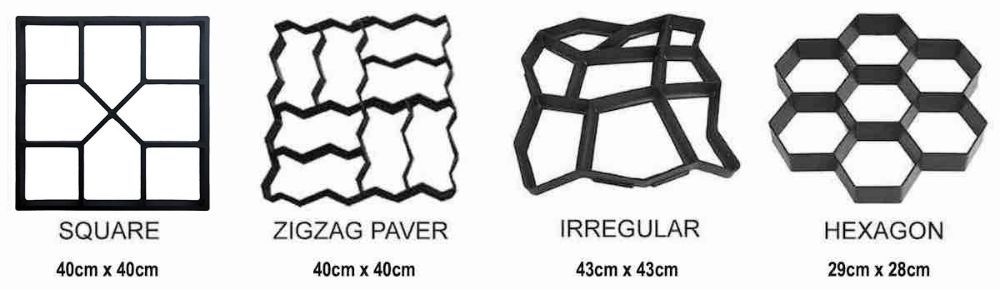

A Variety Of Options to Choose From

FREE FAST DELIVERY ACROSS SINGAPORE ON ALL ORDERS OF $60+ or more (Save $22)

END OF APRIL SUPER SALE … Don’t Miss Out

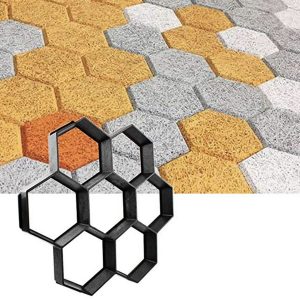

Premium concrete garden moulds that will help you to decorate your garden area

These new & stylish concrete garden moulds use heavy-duty plastic concrete paver moulds that turn pre-mixed concrete into a concrete garden stepping stones, pathways or even complete patio areas.

Bring your garden, backyard or front yard to life with your very own personalised DIY project.

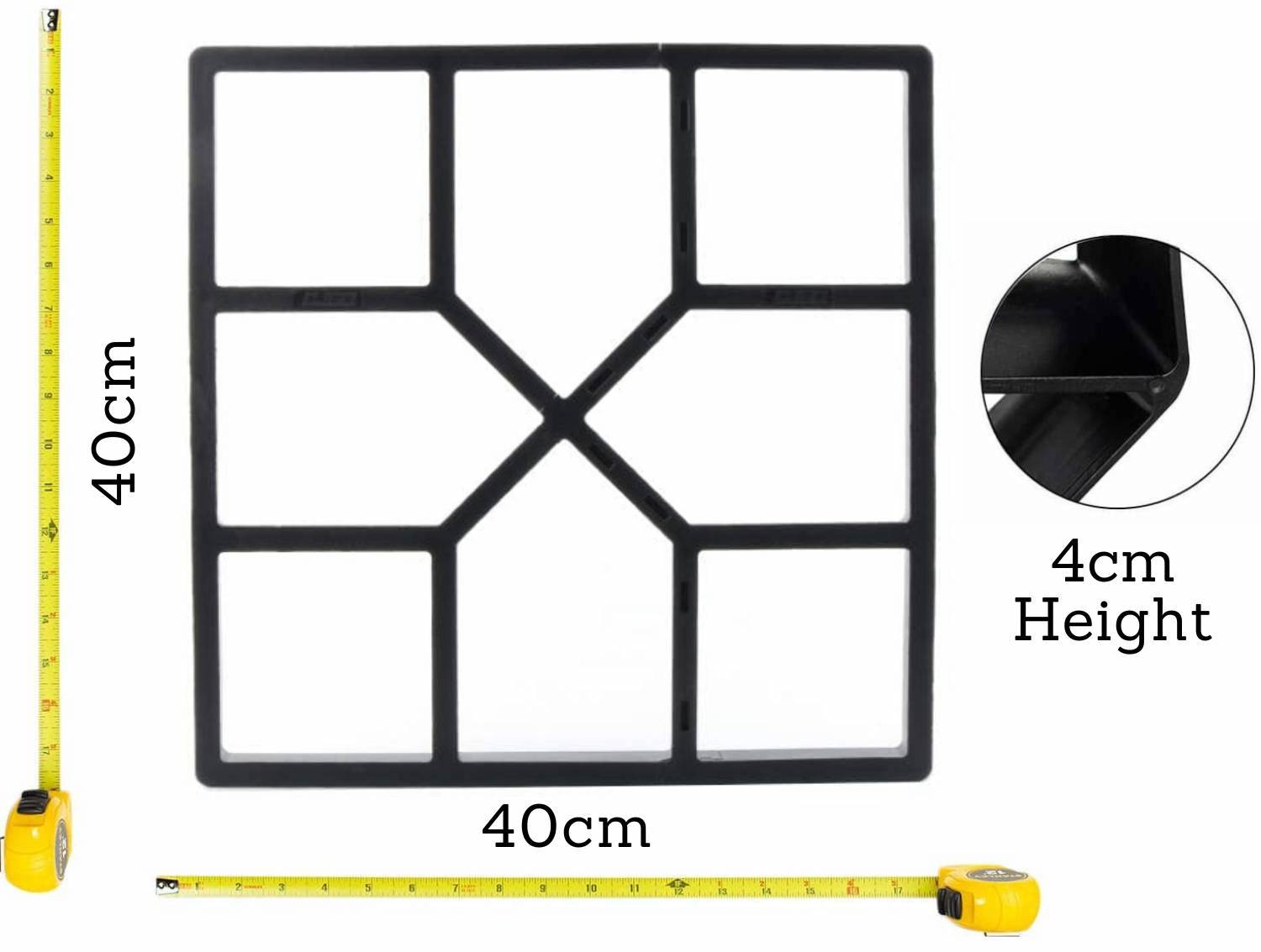

SPECIFICATIONS - Square Mould

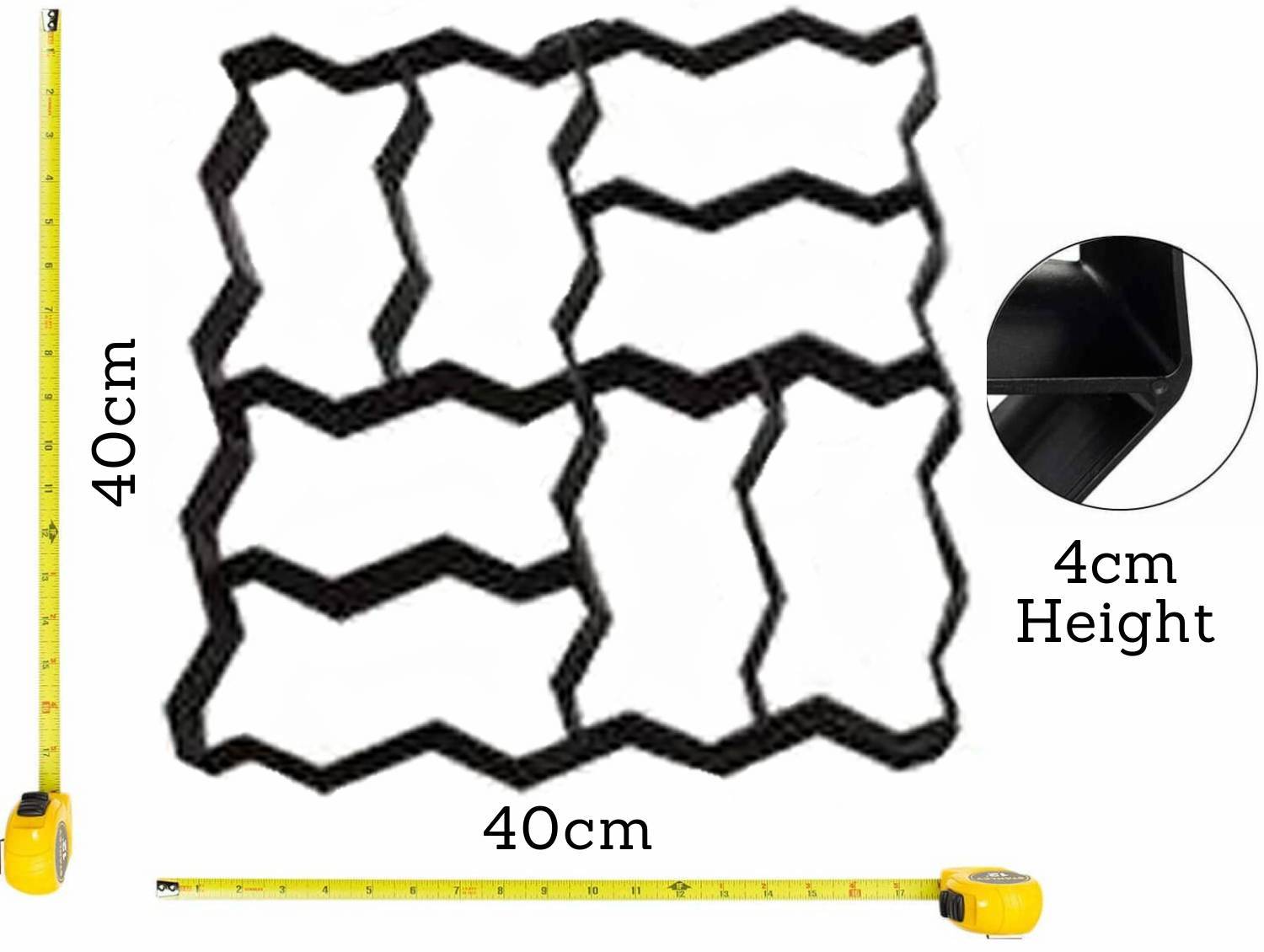

SPECIFICATIONS - ZigZag Mould

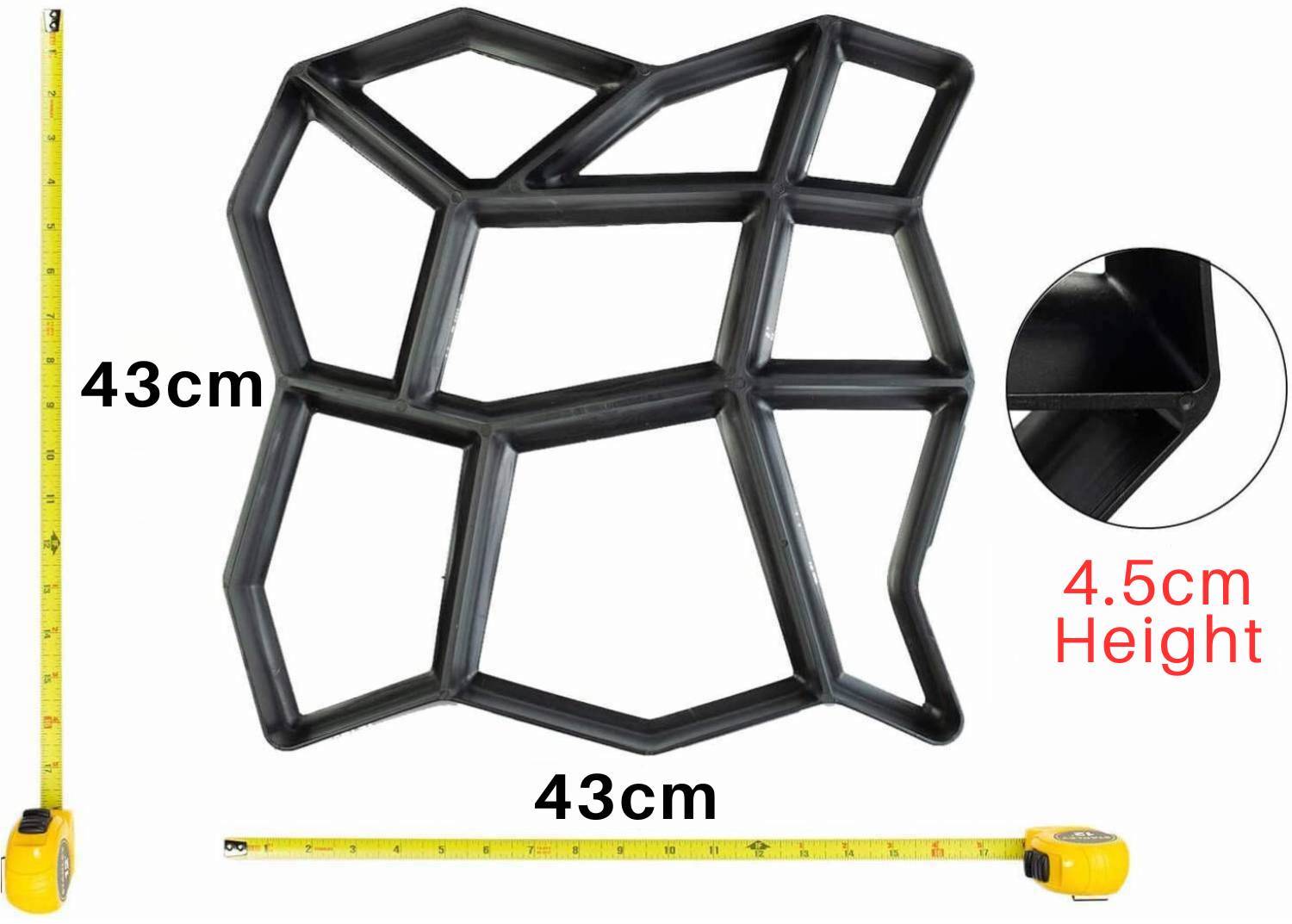

SPECIFICATIONS - Irregular Mould

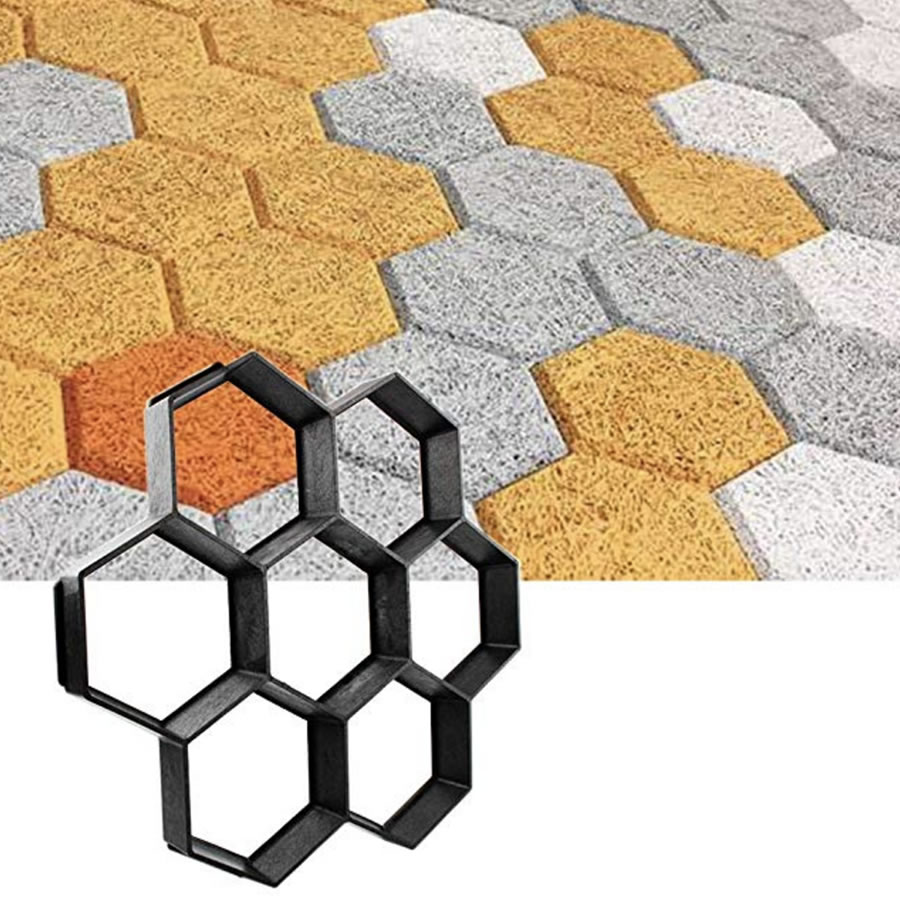

SPECIFICATIONS - Hexagon Mould

DUE TO CURRENT HIGH DEMAND

PLEASE ALLOW 5-7 DAYS DELIVERY

Ordering Online

Which payment methods are accepted?

We currently only accept credit card payments, PayPal & Crypto currency. More payment methods will be added in the future.

What currency are the prices displayed in?

All of our prices are displayed in $SGD

What are your delivery options and how long will it take?

- Singapore: Free delivery, 5-7 days

- Other countries: Free delivery, 5-7 days

OUR DELIVERY PARTNERS

Do I get a receipt for my order?

You will be sent a receipt for your order by email after payment is made. You will also receive a confirmation email with a tracking number once your item has been shipped.

Do you have a shop location?

Can I return my item?

We will gladly Refund or Exchange an item if:

- The item is faulty

- The item is not the same as the description or as shown or advertised

- The item does not perform as per the manufacturers intention

You may not be entitled to a Refund or Exchange if:

- You have changed your mind and no longer require the item

- You decide you cannot afford the item

- You found the item cheaper elsewhere

- The style, colour, or size is not suitable

- You were responsible for the fault

- All refund requests MUST be accompanied with an original receipt or other proof of purchase.

Please feel free to discuss our policy with our Manager prior to purchase.

Note that measurements quoted on our website and affiliated sites and social media channels are subject to slight variances, when purchasing items measure all items to ensure they fit your space.

Product Shipping

How do I know if my order has been shipped?

Once your order is shipped, it will be marked as complete in our database and you will receive a confirmation email with a tracking number.

I haven't received my order yet! Is it lost?

If you have any concerns with your order, please contact our support team by email and they will be glad to assist you. Most emails are answered within 1 business day.

Support Team: [email protected]

Can you use the moulds to make circles, gentle curves, etc. ?

Yes you can….if you do some pre-work first and lay out the borders with bricks this will give you a visual to work within.

You could also dig small trenches where the border bricks were and fill in the space with small landscape pebble to keep the border.

How much concrete does it take to fill one mould?

About 13.8 pounds concrete (3.45 lb. cement + 10.35 lb. sand).

How long does the concrete have to set before removing the mould to do another?

That would depend on the type of concrete you purchase and how you mix it. Generally speaking you can move the mold after about 2 – 3 minutes to the next stamp area.

Can you do a driveway with this? Wondering if the weight of vehicles could easily shift or crack the concrete after awhile?

Yes you could.

With that said these moulds are more for landscaping or stepping stones.

What do you use for the fill in the gaps with?

You can fill the gaps with soil and then put some grass on it. Sand and small gravel is another alternative.

Can the moulds be rotated so that the pattern is less uniform?

Yes, you can rotate this mould to create your own unique patterns.

If you like the random style, you can make the pattern not uniform.

If you like the uniform style, you can also create a uniformed pattern with it.

What do you mean by irregular shape?

The irregular shape mould simply means the pattern of this mould is random, and the shape of it is not square

How would you color these if you wanted each different shape a different color? Sand? concrete pigment?

There are many ways you can change the color of the concrete. Here is a few ideas.

Pigment: you will have to mix the pigment with the concrete that means if you want different colors in each stone you will need multiple mixing buckets. You will need to be very patient with this process because when you screed it you will end up mixing the colors together.

Dye: this is an application that can be painted or sprayed on. You will more than likely need to seal it which can make the concrete mildly slippery when wet.

Paint: oil based paint is also an option you would not want to use latex because it will peel. Oil based paint come in quarts gallons as well as inside a spray can probably not going to be the long lasting result you’re looking for but it should hold up for 2 to 3 Seasons.

Ryan Lee –

Fantastic, just what we needed to make a truly unique and beautiful garden walkway

Chun Hwee Ong –

Easy to use, stepping stones look great!

Ke Wei Ng –

Good product, does the job

Chong Yeow Lim –

Alot of work but well worth it

YongJae Koh –

Arrived and is in excellent condition I am pleased with the purchase

Omar Wu –

as described and fast delivery

Sean Lui –

Excellent!

Xavier Jie –

I bought two so that I can speed up my work. What makes it hard is the fact it’s so easy to use, you come up with complex usage scenarios. That’s where I am. It is awesome and not as SMALL as what a lot of the other sellers are selling

Michelle Wu –

Worked as I was expecting. Ordered 4 so I could do 4 at a time. Four from 80 lb bag of concrete. Weather hasn’t been good. So on hold till clear and warms up.

Eugene Mai –

Great for a DIY…we were excited to have it come.

Michael Wong –

Built pavers over top of a badly cracked and decrepit sidewalk. Different sakrete (lowes) concrete bags yielded slightly different color hues so enabled me to rearrange a random color assortment. Overall the mold held up very well and is going to storage in the event any of these paver stones break.

Ben Wu –

I llike this mold. You can use it over and over. Cleans up well. I use two different color of cement when I am using this mold. You can place the mold so the designs meets.. Love it.

Jason Lim –

Nice product however they really should identify top/bottom better on the mold. I laid 3 sets before realizing the mold was inverted. This causes sharp lines in the concrete.

Alex Li –

simple to use and will hold up for several dozen if not hundreds of uses

Kim Tan –

Ordered because hubby said it would be so much cheaper to make than buy. The mold came quick and look sturdy. Months later all I can say is that they look great in my garage ? !! I will update if we ever use them as intended lol.

Ethan Ng –

Works great I used it with my garden! I work in concrete and this is easy to use.

Victor Lim –

but I would recommend that you use more than one…